Two Israeli companies say they used a specialized 3-D printer to create an environment in which stem cells could grow into a specific tissue.

In the near future, the technology could be used for testing new drugs, but it also opens up the possibility of growing organ replacements.

In 2006, Japanese scientist Shinya Yamanaka and his team discovered that common human cells, such as skin cells, can be turned into stem cells, previously harvested from embryos.

With ethical concerns about using embryonic stem cells removed, many researchers around the world started experimenting with tissue regeneration.

The so-called induced pluripotent stem cells, or IPS cells, are now being used for replacing simpler tissues in the human body lost to disease or injury.

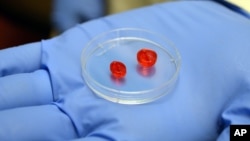

Human stem cells

The process is still slow, but Israeli 3-D printer manufacturer Nano Dimension, and Accellta, a company that produces IPS cells, now say they have tested a 3-D printer capable of fast production of human stem cells.

“I have to emphasize that what we have done so far is a proof of concept. We didn't grow a fully functional human tissue that is actually going to all kind of medical usages," Amit Dror, CEO of Nano Dimension, said.

"What we have proven [is] that we have the ability by combining the know-how and IP [intellectual property] of both companies to get to the right materials and basically being able to print very fast an array which resembles a tissue by using human stem cells," Dror said.

He said special ink containing living stem cells, combined with other substances that stabilize the environment and support their growth, can be printed very quickly.

Another advantage of 3-D printing over manual preparation of substrate for growth of stem cells is the ability to precisely control the ingredients and sequence of their layering.

“It's not good enough just to mix the different components," Dror said. "You want to set them in a way that resembles a human body, because it's not that every layer of tissue within any organ, or skin, or any part of the body has just a mixture of cells. They are located in different concentrations in different places.

"It could be that you have a few cells of one type in one spot and then next to it some different types of cells. The ability to accurately place in the right position the type of cells give them advantage in order to generate a tissue that really resembles the human body," he added.

Functional tissue

William Wagner, director of the University of Pittsburgh’s McGowan Institute for Regenerative Medicine, said printing stem cells in a certain shape is relatively easy, but turning them into functional tissue is going to be a challenge.

However, Wagner said printing a representative slice that behaves like a certain tissue can be very useful.

“Let's say you're looking at a drug that would fix liver disease that causes the liver to not be able to automatically degrade some substance," he said. "Now you have the ability to do a thousand experiments in parallel, with liver tissue, with your drug, assessing the effectiveness of it.”

Wagner said regeneration of complicated human tissues, such as full organs, is still a long way off, so the most likely successes for tissue printing are going to be simpler tissues like skin or muscle, or maybe even as complicated as intestinal wall.