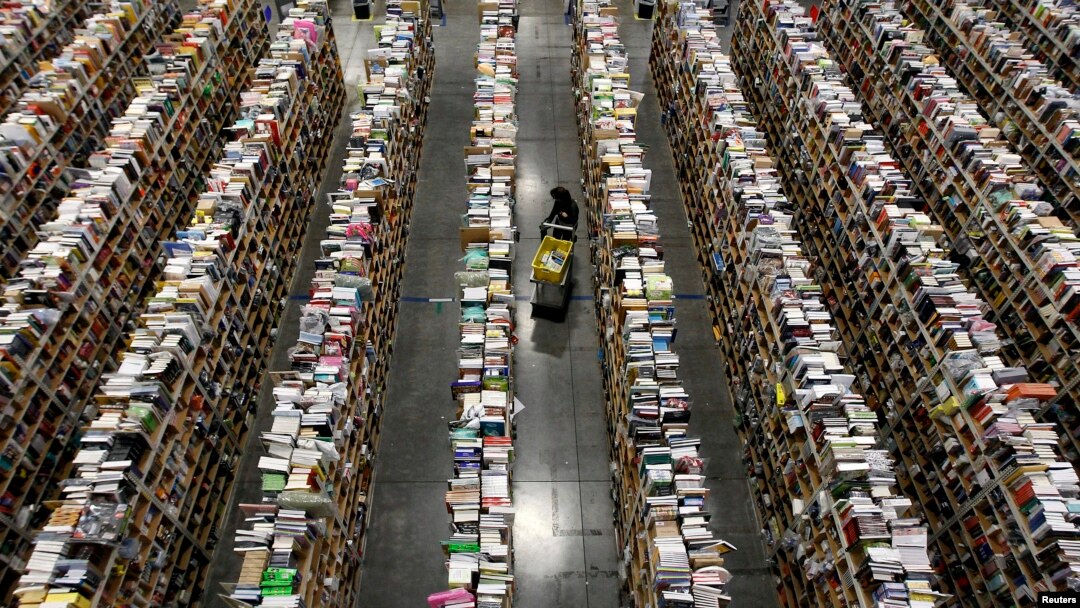

Amazon’s idea of using flying drones for speeding up delivery of its merchandise and lowering the cost may be some years off, but the U.S. retail giant is already employing droves of autonomous robots in its huge warehouse in Seattle, Washington.

According to reports in Wall Street Jornal and technology website technologyadvice.com, the warehouse robots could save Amazon as much as 40 percent of the cost of fulfilling orders.

About one foot high, battery-powered orange boxes, the size of a lawn mower, with hidden wheels that can drive them in all directions and turn in place, crisscross the smooth floor of the warehouse, lifting and shuttling shelves with different kinds of merchandise.

Cameras located underside scan coded directions painted on the floor while the central computer wirelessly gives orders to the cars to deliver the goods to human packers. When a robot receives the order for certain merchandise it identifies the shelf containing the ware, lifts it just a few inches off the floor and carries it to a worker, who only has to place the item into a box on a conveyer belt to the shipping department.

The robots, designed by Kiva Systems, navigate quickly and efficiently through the warehouse, never colliding and never dropping a shelf.

In its third quarter earnings report Amazon says about 1,400 Kiva robots work in three of its warehouses. The retail giant also disclosed that it actually bought Kiva Systems in March 2012 for $775 million.

According to one analyst Kiva robots could save Amazon between 458 and 916 millions of dollars annually. It is not known how workers feel about the warehouse robots but they clearly replace humans in one of the most exhausting jobs.

Kiva robots are employed in warehouses of other U.S. companies like Zappos, Walgreens and the office supply giant Staples.

According to reports in Wall Street Jornal and technology website technologyadvice.com, the warehouse robots could save Amazon as much as 40 percent of the cost of fulfilling orders.

About one foot high, battery-powered orange boxes, the size of a lawn mower, with hidden wheels that can drive them in all directions and turn in place, crisscross the smooth floor of the warehouse, lifting and shuttling shelves with different kinds of merchandise.

Cameras located underside scan coded directions painted on the floor while the central computer wirelessly gives orders to the cars to deliver the goods to human packers. When a robot receives the order for certain merchandise it identifies the shelf containing the ware, lifts it just a few inches off the floor and carries it to a worker, who only has to place the item into a box on a conveyer belt to the shipping department.

The robots, designed by Kiva Systems, navigate quickly and efficiently through the warehouse, never colliding and never dropping a shelf.

In its third quarter earnings report Amazon says about 1,400 Kiva robots work in three of its warehouses. The retail giant also disclosed that it actually bought Kiva Systems in March 2012 for $775 million.

According to one analyst Kiva robots could save Amazon between 458 and 916 millions of dollars annually. It is not known how workers feel about the warehouse robots but they clearly replace humans in one of the most exhausting jobs.

Kiva robots are employed in warehouses of other U.S. companies like Zappos, Walgreens and the office supply giant Staples.